Common problem

Electrolytic capacitor damage phenomenon

Source:本站 | Time:2022-02-21 | Read:713

Electrolytic capacitors are used a lot in electrical equipment, and due to the uneven quality of electrolytic capacitors on the market, the phenomenon of capacitor failure has often occurred.

Electrolytic capacitor damage has the following performances.

1: complete loss of capacity or small capacity.

2: slight or serious leakage phenomenon.

3: Capacitor loses capacity or has small capacity and leakage phenomenon.

The methods to find the damaged and unqualified capacitors are as follows

1: Look: some capacitors will leak when damaged, and there is a layer of oil on the surface of the circuit board under the capacitor or even on the exterior of the capacitor. This kind of capacitor can never be used to work; some capacitors will bulge after damage, which is also not allowed to use.

2: Touch: Some electrolytic capacitors with serious leakage will be hot after power on, and even hot when you touch them with your hands, then you need to replace the capacitor in time.

3: Electrolytic capacitor has electrolyte inside, long time baking will make the electrolyte dry and lead to capacity reduction, so focus on checking the capacitor near the heat sink and high power components, the closer it is, the more likely it will be damaged.

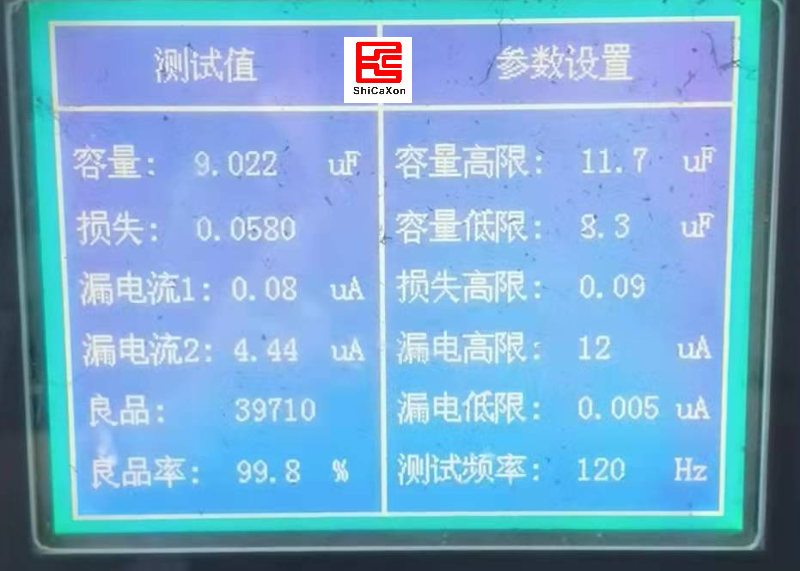

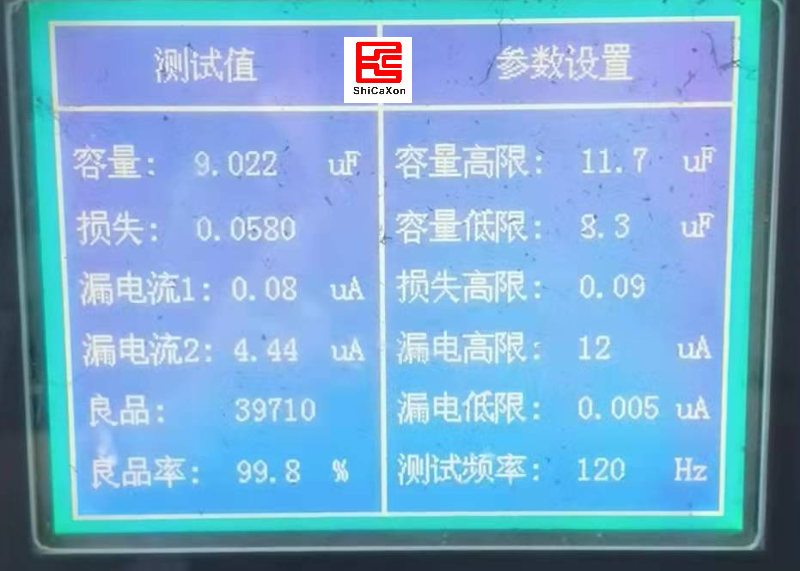

ShiCaXon Capacitors strictly controls the yield rate, the raw materials use electrolyte, aluminum foil, casing, etc. The produced capacitors are tested by aging machine, and each capacitor needs to be tested manually, the yield rate is more than 99%.

Electrolytic capacitor damage has the following performances.

1: complete loss of capacity or small capacity.

2: slight or serious leakage phenomenon.

3: Capacitor loses capacity or has small capacity and leakage phenomenon.

The methods to find the damaged and unqualified capacitors are as follows

1: Look: some capacitors will leak when damaged, and there is a layer of oil on the surface of the circuit board under the capacitor or even on the exterior of the capacitor. This kind of capacitor can never be used to work; some capacitors will bulge after damage, which is also not allowed to use.

2: Touch: Some electrolytic capacitors with serious leakage will be hot after power on, and even hot when you touch them with your hands, then you need to replace the capacitor in time.

3: Electrolytic capacitor has electrolyte inside, long time baking will make the electrolyte dry and lead to capacity reduction, so focus on checking the capacitor near the heat sink and high power components, the closer it is, the more likely it will be damaged.

ShiCaXon Capacitors strictly controls the yield rate, the raw materials use electrolyte, aluminum foil, casing, etc. The produced capacitors are tested by aging machine, and each capacitor needs to be tested manually, the yield rate is more than 99%.