Common problem

About ESR of electrolytic capacitors

Source:本站 | Time:2022-04-26 | Read:843

I. First of all, ESR.

??As the output rectifier filter capacitor of switching power supply, the capacitance is often the primary choice. You can reduce ESR by connecting multiple capacitors in parallel, or you can choose a larger capacitance to reduce ESR.

??ESR is the most important performance parameter of high frequency electrolytic capacitors, and many capacitor suppliers emphasize the performance feature of "LOW ESR", which means very small ESR value. So, how do we understand the actual meaning of LOW ESR correctly? Due to the development of electronic technology now, the voltage supplied to the hardware is showing a trend of lower and lower, for example, the power supply voltage of FPGA, DSP, RAM series are very low, some circuit voltage is less than 2V, compared with the previous voltage of 3, 4V to be much lower. But, on the other hand, these chips due to transistor and frequency explosion, the demand for power consumption is increasing, so according to the formula of P = UI to calculate the current requirements of these devices is increasingly high.

??For example, in the computer motherboard, for example, two power consumption is the same 70W CPU, the former voltage is 3.3V, the latter voltage is 1.8V. then, the former current is I = P / U = 70W / 3.3V about 21.2A. And the current of the latter is I=P/U=70W/1.8V=38.9A, which reaches nearly double of the former. With higher and higher currents through the capacitor, if the ESR value of the capacitor cannot be kept in a smaller range, a higher ripple voltage than before will be generated (the ideal output DC voltage should be a horizontal line, while the ripple voltage is the peaks and valleys on the horizontal line).

??In addition, even the same ripple voltage will have a greater impact on a low voltage circuit than in a high voltage case. For example, for a 3.3V MCU, the 0.2V ripple voltage is small enough to be fatal, but for FPGAs and DSPs powered by 1.8V, the same 0.2V ripple voltage is large enough to cause errors in the digital circuit.

??So what is the relationship between ESR value and ripple voltage? We can use the following formula to express.

??V=R(ESR)×I

??The V in this formula indicates the ripple voltage, while R indicates the ESR of the capacitor and I indicates the current. As you can see, when the current increases, the ripple voltage will increase exponentially even if the ESR remains the same, so it is imperative to use capacitors with lower ESR values. This is why the capacitors used on today's hardware devices such as boards are increasingly emphasizing low ESR.

??II. Why manufacturers don't want to label the ESR?

??From the production process of electrolytic capacitors, the resistance of the electrolyte is the main part of the equivalent series resistance (ESR) of aluminum electrolytic capacitors. The main reason why most aluminum electrolytic capacitor manufacturers do not give ESR data is that the ESR of aluminum electrolytic capacitors is too large compared to other dielectric capacitors. For example, for a 1μF/16V ordinary aluminum electrolytic capacitor, the ESR is usually around 20Ω; for a 100μF aluminum electrolytic capacitor, the ESR is also between 1.5~2Ω.

??Imagine, such data written in the datasheet will definitely affect the confidence of the application of aluminum electrolytic capacitors. Therefore, in a way or more, applying aluminum electrolytic capacitors is a helpless choice. It will affect the application of aluminum electrolytic capacitors.

??For general application aluminum electrolytic capacitors, most aluminum electrolytic capacitor manufacturers do not give ESR data, while for low ESR aluminum electrolytic capacitors for switching power supplies or plug-in aluminum electrolytic capacitors with higher capacitance, this data is given.

??III. By the way, there are several capacitor parameters that are not indicated

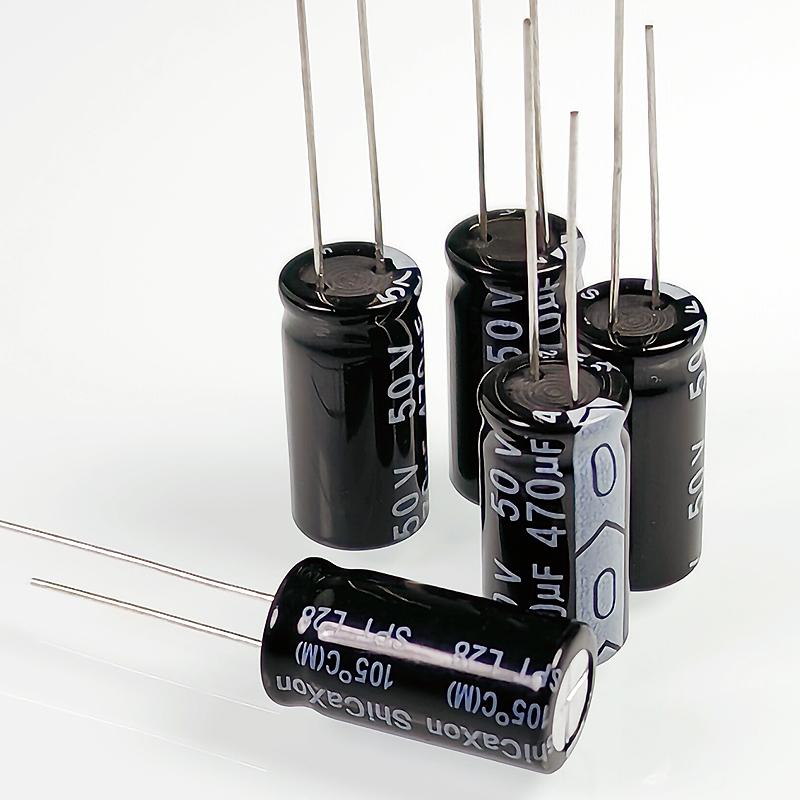

??In fact, as a hardware engineer, we always have the feeling that the capacitor parameters are divided into "explicit parameters" and "implicit parameters". The so-called "explicit parameters" are some basic parameters printed on the surface of the capacitor, which we can often know directly after seeing a capacitor. For example, the capacitance (e.g. "470μF", etc.), capacity deviation range, temperature range, voltage value (e.g. "16V").

??The so-called "hidden parameters" are the parameters that we need to check according to the capacitor model. For example, the ESR value, which we often talk about, has become an important parameter to distinguish the performance of capacitors, but we can't see this parameter on the capacitor, we have to go to the relevant website to check it by the capacitor model number. There are many similar parameters with the same fate as ESR, including some of the following.

??1. rated ripple current value; said rated ripple current will generate loss in its ESR and make the aluminum electrolytic capacitor heat up, the limit of this heat up on the ripple current is the rated ripple current value. It is defined as the maximum ripple current value that can ensure the rated life time of the aluminum electrolytic capacitor at the maximum operating temperature. For general application aluminum electrolytic capacitors, most aluminum electrolytic capacitor manufacturers do not give the ripple current rating data, but for low ESR aluminum electrolytic capacitors for switching power supplies or plug-in aluminum electrolytic capacitors with higher capacitance, this data is given.

??2. The ripple current value that can be withstood; it is explained above.

??The tangent of loss angle (TAN); it corresponds to the ratio of reactive power to active power, this value is related to the quality of the capacitor and the heat generation, the smaller the value the better the capacitor performance.

??4. Leakage current value; no matter how big the insulator is, there will always be a slight current leakage through the capacitor, and this value represents the specific leakage amount. The manufacturer is not willing to label this parameter in detail.

??5. ESL equivalent inductance; ESL equivalent inductance often becomes part of the ESR, and ESL can also cause some circuit failures, such as series resonance, etc.. However, the proportion of ESL is too small compared with the capacity, and the chance of problems is very small, plus the progress of capacitor manufacturing process, nowadays, ESL is gradually ignored, and ESR is the main reference factor besides capacity.

??In fact, to care about these capacitor parameters is to care about the service life of the capacitor, not much to say, other information or online have a lot of introduction.

??As a result, most of the aluminum electrolytic capacitor manufacturers do not give ESR data mainly because the ESR of aluminum electrolytic capacitors seems too large compared to other dielectric capacitors (except for individual ones such as those of individual Japanese companies). Among the many manufacturers of aluminum electrolytic capacitors around the world, few of them can give the equivalent series resistance (ESR) of the aluminum electrolytic capacitors they produce. Some of them don't have such data (such as many domestic aluminum electrolytic capacitor manufacturers), while some of them are required by technical secrecy, and of course, some of them feel that the ESR value of their aluminum electrolytic capacitors is too large and too shy to be published.

??As the output rectifier filter capacitor of switching power supply, the capacitance is often the primary choice. You can reduce ESR by connecting multiple capacitors in parallel, or you can choose a larger capacitance to reduce ESR.

??ESR is the most important performance parameter of high frequency electrolytic capacitors, and many capacitor suppliers emphasize the performance feature of "LOW ESR", which means very small ESR value. So, how do we understand the actual meaning of LOW ESR correctly? Due to the development of electronic technology now, the voltage supplied to the hardware is showing a trend of lower and lower, for example, the power supply voltage of FPGA, DSP, RAM series are very low, some circuit voltage is less than 2V, compared with the previous voltage of 3, 4V to be much lower. But, on the other hand, these chips due to transistor and frequency explosion, the demand for power consumption is increasing, so according to the formula of P = UI to calculate the current requirements of these devices is increasingly high.

??For example, in the computer motherboard, for example, two power consumption is the same 70W CPU, the former voltage is 3.3V, the latter voltage is 1.8V. then, the former current is I = P / U = 70W / 3.3V about 21.2A. And the current of the latter is I=P/U=70W/1.8V=38.9A, which reaches nearly double of the former. With higher and higher currents through the capacitor, if the ESR value of the capacitor cannot be kept in a smaller range, a higher ripple voltage than before will be generated (the ideal output DC voltage should be a horizontal line, while the ripple voltage is the peaks and valleys on the horizontal line).

??In addition, even the same ripple voltage will have a greater impact on a low voltage circuit than in a high voltage case. For example, for a 3.3V MCU, the 0.2V ripple voltage is small enough to be fatal, but for FPGAs and DSPs powered by 1.8V, the same 0.2V ripple voltage is large enough to cause errors in the digital circuit.

??So what is the relationship between ESR value and ripple voltage? We can use the following formula to express.

??V=R(ESR)×I

??The V in this formula indicates the ripple voltage, while R indicates the ESR of the capacitor and I indicates the current. As you can see, when the current increases, the ripple voltage will increase exponentially even if the ESR remains the same, so it is imperative to use capacitors with lower ESR values. This is why the capacitors used on today's hardware devices such as boards are increasingly emphasizing low ESR.

??II. Why manufacturers don't want to label the ESR?

??From the production process of electrolytic capacitors, the resistance of the electrolyte is the main part of the equivalent series resistance (ESR) of aluminum electrolytic capacitors. The main reason why most aluminum electrolytic capacitor manufacturers do not give ESR data is that the ESR of aluminum electrolytic capacitors is too large compared to other dielectric capacitors. For example, for a 1μF/16V ordinary aluminum electrolytic capacitor, the ESR is usually around 20Ω; for a 100μF aluminum electrolytic capacitor, the ESR is also between 1.5~2Ω.

??Imagine, such data written in the datasheet will definitely affect the confidence of the application of aluminum electrolytic capacitors. Therefore, in a way or more, applying aluminum electrolytic capacitors is a helpless choice. It will affect the application of aluminum electrolytic capacitors.

??For general application aluminum electrolytic capacitors, most aluminum electrolytic capacitor manufacturers do not give ESR data, while for low ESR aluminum electrolytic capacitors for switching power supplies or plug-in aluminum electrolytic capacitors with higher capacitance, this data is given.

??III. By the way, there are several capacitor parameters that are not indicated

??In fact, as a hardware engineer, we always have the feeling that the capacitor parameters are divided into "explicit parameters" and "implicit parameters". The so-called "explicit parameters" are some basic parameters printed on the surface of the capacitor, which we can often know directly after seeing a capacitor. For example, the capacitance (e.g. "470μF", etc.), capacity deviation range, temperature range, voltage value (e.g. "16V").

??The so-called "hidden parameters" are the parameters that we need to check according to the capacitor model. For example, the ESR value, which we often talk about, has become an important parameter to distinguish the performance of capacitors, but we can't see this parameter on the capacitor, we have to go to the relevant website to check it by the capacitor model number. There are many similar parameters with the same fate as ESR, including some of the following.

??1. rated ripple current value; said rated ripple current will generate loss in its ESR and make the aluminum electrolytic capacitor heat up, the limit of this heat up on the ripple current is the rated ripple current value. It is defined as the maximum ripple current value that can ensure the rated life time of the aluminum electrolytic capacitor at the maximum operating temperature. For general application aluminum electrolytic capacitors, most aluminum electrolytic capacitor manufacturers do not give the ripple current rating data, but for low ESR aluminum electrolytic capacitors for switching power supplies or plug-in aluminum electrolytic capacitors with higher capacitance, this data is given.

??2. The ripple current value that can be withstood; it is explained above.

??The tangent of loss angle (TAN); it corresponds to the ratio of reactive power to active power, this value is related to the quality of the capacitor and the heat generation, the smaller the value the better the capacitor performance.

??4. Leakage current value; no matter how big the insulator is, there will always be a slight current leakage through the capacitor, and this value represents the specific leakage amount. The manufacturer is not willing to label this parameter in detail.

??5. ESL equivalent inductance; ESL equivalent inductance often becomes part of the ESR, and ESL can also cause some circuit failures, such as series resonance, etc.. However, the proportion of ESL is too small compared with the capacity, and the chance of problems is very small, plus the progress of capacitor manufacturing process, nowadays, ESL is gradually ignored, and ESR is the main reference factor besides capacity.

??In fact, to care about these capacitor parameters is to care about the service life of the capacitor, not much to say, other information or online have a lot of introduction.

??As a result, most of the aluminum electrolytic capacitor manufacturers do not give ESR data mainly because the ESR of aluminum electrolytic capacitors seems too large compared to other dielectric capacitors (except for individual ones such as those of individual Japanese companies). Among the many manufacturers of aluminum electrolytic capacitors around the world, few of them can give the equivalent series resistance (ESR) of the aluminum electrolytic capacitors they produce. Some of them don't have such data (such as many domestic aluminum electrolytic capacitor manufacturers), while some of them are required by technical secrecy, and of course, some of them feel that the ESR value of their aluminum electrolytic capacitors is too large and too shy to be published.