Common problem

Do e-cap really cause the short life of LED lamps?

So what is the actual situation?

1、The life span of electrolytic capacitor depends on the ambient temperature when it works

??How is the life of electrolytic capacitor defined? Of course, it is defined in hours. But if the life expectancy of an electrolytic capacitor is 1,000 hours, it doesn't mean that the capacitor will be broken after 1,000 hours, no, it just means that the capacity of the capacitor will be reduced by half after 1,000 hours, originally it was 20uF, now it is only 10uF.

??In addition, the life time indicator of electrolytic capacitor has another characteristic, which is to state the life time under the working temperature of how many degrees. And it is usually specified as the life time at 105℃ ambient temperature.

??This is because the electrolytic capacitors we use nowadays are all electrolytic capacitors with liquid electrolyte, and if the electrolyte dries up, the capacity will be gone. The higher the temperature is, the more easily the electrolyte will evaporate. So the life index of electrolytic capacitors must indicate the life under what ambient temperature.

??That's why all electrolytic capacitors are currently marked with the life at 105℃. For example, the life time of the most common electrolytic capacitor is only 1,000 hours at 105℃. But if you think that all electrolytic capacitors have a life time of 1,000 hours. That would be a big mistake.

??Simply put, if the ambient temperature is higher than 105°C, then the life time is lower than 1,000 hours, and if the ambient temperature is lower than 105°C, then the life time is higher than 1,000 hours. So is there a rough quantitative relationship between life span and temperature? Yes, there is!

??There is a most simple and easy to calculate relationship, that is, for every 10 degrees increase in ambient temperature, the life span will be reduced by half; conversely, for every 10 degrees decrease in ambient temperature, the life span will be doubled. Of course this is just a simple estimate, but it is quite accurate.

??Because the electrolytic capacitors used in the LED driver power supply are definitely placed inside the LED lighting housing, so we just need to know the temperature inside the LED lighting to know the working life of the electrolytic capacitors.

??2、What is the ambient temperature in LED lamps and lanterns?

??Because LED and electrolytic capacitor are placed in the same housing in many lamps, simply speaking, the ambient temperature of both is the same. And this ambient temperature is mainly determined by the balance of heat and heat dissipation of LED and power supply. And each LED lighting heat and heat dissipation is not the same, so how can we know the ambient temperature?

??In fact, this problem can be projected in reverse, that is, a well-designed LED luminaire, it allows the internal ambient temperature should be a certain. This is because the junction temperature of the LED chip is the main reason to determine the LED chip light failure (life), LED junction temperature is of course also related to its ambient temperature, so as long as we know the allowable LED junction temperature, we can also project the internal ambient temperature of the LED luminaire.

??But there are at least three thermal resistance, that is, the LED chip junction to the shell of the thermal resistance θjc, and the LED shell to the surface of the aluminum substrate thermal resistance, which in fact after the solder, copper foil, and insulation layer and then to the aluminum plate, but the most important of which is the thermal resistance of the insulation layer, collectively referred to as θlv, the third is the thermal resistance of the aluminum plate to the air inside the bubble θla.

??Take the 3014 LED, its own thermal resistance θjc is 90 ℃ / W, because its power is only 0.1W, so the temperature difference between inside and outside is 9 ℃. Aluminum substrate thermal resistance is 1 ℃ / W, for a 10W lamps and lanterns because all 10W LEDs are installed on the same aluminum substrate, so its total temperature difference is 10 ℃, a total of 19 ℃ temperature difference, the final θla is difficult to estimate, because it is related to whether the air flow, in the case of internal air does not flow, the temperature difference is probably only about 1 ℃, so it adds up to a total of 20 ℃ . In other words, the LED junction temperature is equal to the ambient temperature plus 20°C.

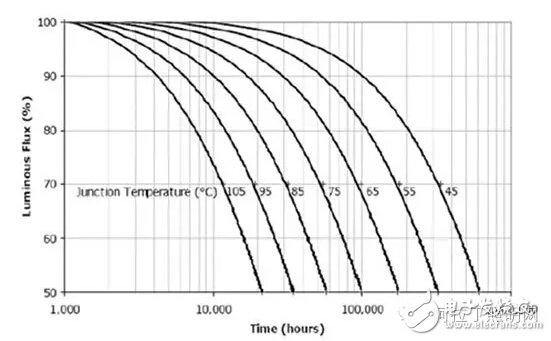

??So the ambient temperature inside the bubble case can allow 105 degrees? Just take a look at one of the pictures below to find out. That is the relationship between the junction temperature and light decay of LED chips from Cree.

If the ambient temperature is 105°C, then at least 20°C must also be added to the junction temperature, so the junction temperature would be about 125°C. It is no longer possible to check on this curve, so we can only roughly estimate its life time to be only 4,000 hours. This is absolutely unacceptable! In other words, the ambient temperature in the LED bubble must be much lower than 105 ℃! We can in turn according to the required LED life to see what its ambient temperature should be. Assuming we require the LED life to be 100,000 hours, then its junction temperature can only be lower than 65℃, so the ambient temperature must be lower than 45℃. In other words, the working ambient temperature of electrolytic capacitor must be lower than 45℃.

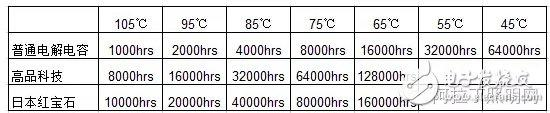

3、The actual life time of various life time electrolytic capacitors at 45℃ ambient temperature

??Now that we know the operating ambient temperature of electrolytic capacitors in actual LED lamps, it is easy to calculate its actual life time. We have listed the actual life time of several common electrolytic capacitors in the table below.

As you can see from the table, even the most common electrolytic capacitor with 1,000 hours of life can reach 64,000 hours at an ambient temperature of 45℃, which is enough for ordinary LED lamps with a nominal 50,000 hours.

4、Ways to extend the life of electrolytic capacitor

??4.1 Extend the life time by design

??In fact, to extend the life of electrolytic capacitor, the method is very simple, because its end of life is mainly because of the liquid electrolyte evaporation, if improve its sealing, not to let it evaporate, its life will be naturally extended. For example, Evox Rifa has designed a double-layer sealing system to slow down the evaporation rate of electrolyte.

??Also, the loss of electrolyte can be greatly reduced by using phenolic plastic cover with electrodes and double special sealing gaskets to bite closely with the aluminum case.

??4.2 Extend the life of the electrolyte from the use

??If the ripple current is too large, it can be reduced by connecting two capacitors in parallel.

??4.3 Extend the life of capacitor by selection

??When choosing electrolytic capacitors, besides using the brand electrolytic capacitors to ensure the quality, we also need to leave a margin in voltage and capacity. For example, after the bridge rectification, the DC voltage of 220V will be 300V, but at least 450V capacitor should be used in the selection of electrolytic capacitor. These measures can also extend the life of electrolytic capacitors. Because the equivalent resistance and ripple current of the capacitor will make its internal temperature higher than the ambient temperature, so leaving a margin is necessary.

??5、Protection of electrolytic capacitors

??Sometimes even though long life electrolytic capacitor is used, but still often find the electrolytic capacitor is broken, what is the reason?

??In fact, if you think it is the quality of electrolytic capacitor is not good, it is really let the electrolytic capacitor suffer the injustice! In fact, electrolytic capacitors are not the perpetrators, but the victims at this time. Why do you say so?

??Because we know that in the mains AC network, there are often instantaneous high voltage surges due to lightning strikes, and although a lot of lightning protection measures have been done on the power grid, there are still inevitably fish that leak into people's homes.

??The U.S. power grid should be very advanced, but in my home on an incident, after a lightning strike, I found my fax machine can not work, after careful examination, the original because of lightning strikes and the power supply completely broken, can only be scrapped.

??For LED lamps and lanterns if the utility power supply, then the power supply in the lamps and lanterns must be in the utility input plus anti-surge measures, including fuses, and overvoltage protection resistors, usually called varistors, to protect the components behind, otherwise the long life of the electrolytic capacitors will also be knocked out by the surge voltage.

(Article extracted from: electronic fever network Aladdin lighting network)